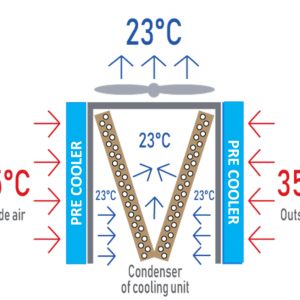

AboutCondenser Pre-cooler For Air Cooled Chillers

The performance of air-cooled chillers is impacted to a great extent by the temperature of the ambient air which is used to extract heat from air-cooled condensers. Airmaaster Condenser Pre-Coolers (ACPC) helps pre cool this ambient air before it passes through the condenser, thus improving the overall efficiency of the chiller. Pre cooling the air enables the condenser to reject more heat thus reducing the electrical demand as well as increasing the cooling capacity.

Airmaaster ACPC uses special grade high efficiency

engineered corrugated heat and mass transfer

mediums to pre cool the ambient air. The medium is

well supported using non corrosive aluminum fixtures.

The system comes with a well-engineered water

treatment and distribution system coupled with

optional control systems.

The heat and mass transfer medium is wetted using treated water. The ambient air when it passes through this medium gets evenly cooled as the water evaporates. The water evaporated from the surface is in vapor form and does not add any corrosive or contaminating elements into the air stream. The systems are designed with water recirculation

mechanism to avoid water wastage.

BENEFITS

- Reduced energy consumption of compressors due to reduction in compression ratio

- Increase in cooling capacity of chillers due to reduction in refrigerant condensing temperature

- Reduction in energy consumption due to increase in compressor unloading time

- Reduced maintenance cost of chillers since air gets pre-filtered before reaching condenser

- Reduced wear and tear and increased life expectancy of compressor since loading time is reduced

- Easy to install, modular construction which can be easily removed for service access

- Available in all ranges – for ODUs, VRVs and packaged chillers

- Solution is flexible based on water quality

- Payback lesser than 2 years